You’ll notice the difference when working with a top-tier membrane switch manufacturer.

You’ll notice the difference when working with a top-tier membrane switch manufacturer.

Blog Article

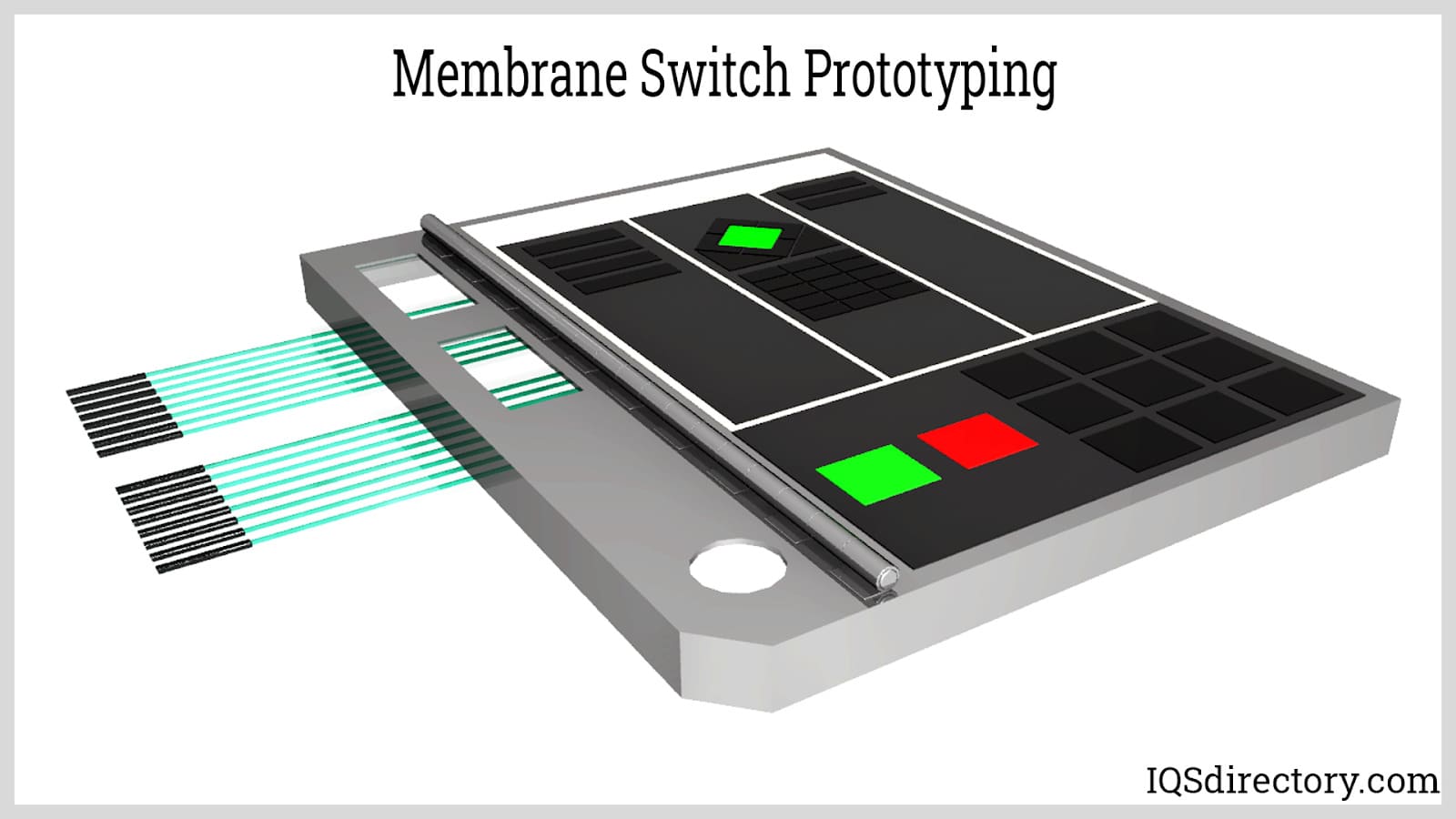

Everything About Membrane Layer Change: Comprehending Its Design and Functionality

When you believe about the control user interfaces in modern-day gadgets, membrane layer buttons commonly come to mind. Allow's explore what collections membrane layer switches over apart from other control systems.

What Are Membrane Layer Switches?

Membrane switches can additionally be customized concerning shape, dimension, and graphics, allowing manufacturers to create distinct user interfaces customized to details products. In general, membrane layer buttons play a considerable duty in enhancing customer experience throughout a broad variety of applications.

Exactly How Membrane Layer Changes Work

When you push a secret on a membrane layer button, it triggers an uncomplicated yet reliable mechanism. The leading layer, commonly made of flexible material, presses down onto a conductive layer below it. This activity bridges the void in between conductive traces, completing an electric circuit. As quickly as the circuit shuts, it sends a signal to the tool's controller, which analyzes your input.

You'll discover that the responsive comments varies based on the switch style, offering either a soft click or an extra obvious reaction. As soon as you launch the secret, the membrane go back to its initial position, resuming the circuit and quiting the signal. This procedure takes place nearly instantaneously, making certain a receptive customer experience.

Membrane layer switches are prominent because of their durability and resistance to dirt and dampness, making them optimal for various applications, from house home appliances to medical devices. Comprehending this operation helps you value their prevalent use.

Key Parts of Membrane Buttons

Understanding the crucial elements of membrane buttons is essential for grasping their capability and design. At the core, you'll locate the graphic overlay, which offers the visual user interface for individuals. Beneath that, there's a spacer layer that divides the circuit layers, ensuring that they don't make contact till pressed. The circuit layer is where the magic takes place; it is composed of conductive traces that finish the circuit when you push the switch. Another vital element is the sticky support, permitting the button to abide by surface areas securely. The safety layer guards versus ecological variables and wear, expanding the button's life expectancy. Each component plays a substantial role in making sure dependable performance and customer interaction. By understanding these parts, you'll get insight right into exactly how membrane switches run and their value in various applications.

Products Made Use Of in Membrane Switch Over Layout

The efficiency and resilience of membrane layer changes greatly depend upon the products used in their style. You normally come across polyester and polycarbonate as primary substrates because of their excellent toughness and flexibility. These products withstand scratches and chemicals, making them perfect for demanding settings.

The conductive layers usually make use of silver or carbon, chosen for their dependability and conductivity. membrane switch manufacturer. Silver offers superior efficiency, while carbon is an economical option. For the overlay, you might think about a matte or glossy coating, depending upon your visual needs and user experience

Make specific to choose adhesives that withstand environmental aspects like temperature level and humidity. Choosing the appropriate materials will ensure your membrane button stands the test of time.

Layout Considerations for Membrane Layer Switches

While creating membrane switches, it's crucial to take into account various elements that affect their functionality and user experience. Start by concentrating on the format and button dimension; make certain they're user-friendly and simple to navigate.

Do not forget the visuals layout; clear labeling webpage and shade contrast are considerable for presence. Validate your layout fits ecological aspects, like wetness or temperature level variants, which can influence performance. Bear in mind the significance of testing models with genuine users to collect comments and make essential adjustments. This repetitive procedure helps you refine the design, validating it fulfills both functional and aesthetic requirements successfully. By very carefully taking into consideration these aspects, you'll create a membrane button that enhances use and satisfaction.

Applications of Membrane Layer Switches

Membrane switches are versatile components discovered in various applications, from industrial equipment to consumer electronic devices. You'll see their influence in equipments that need long lasting user interfaces and in devices that benefit from streamlined layouts. Recognizing these applications aids you value the functionality and usefulness of membrane layer switches in everyday innovation.

Industrial Equipment Use

When you're seeking to improve the functionality of industrial tools, membrane layer switches offer a reliable solution that incorporates longevity with straightforward layout. These buttons are ideal for harsh settings, offering resistance to dirt, moisture, and chemicals. You'll find them in control panels for making makers, HVAC systems, and medical gadgets, where accuracy and responsiveness are important. Their low account implies they fit effortlessly right into different devices, saving useful room while keeping simplicity of use. With personalized graphics and backlighting choices, you can produce an intuitive user interface for drivers, improving efficiency and safety and security. And also, their lengthy life-span minimizes maintenance prices, making them a wise financial investment for your industrial applications. Welcome membrane buttons to streamline your procedures and improve total efficiency.

Consumer Electronic Devices Assimilation

In the domain of consumer electronics, membrane switches play a crucial role in improving customer communication see this here and tool functionality. Membrane layer buttons likewise ensure sturdiness and resistance to dirt and wetness, prolonging the life expectancy of your electronics. By selecting membrane layer buttons, you boost not simply the functionality but additionally the style of your gadgets, making daily interactions smooth and enjoyable.

Advantages and Disadvantages of Membrane Layer Switches

While membrane buttons use a variety of advantages, they likewise come with some downsides that you should take into consideration. One considerable advantage is their compact style, making them optimal for space-constrained applications.

Nonetheless, there are drawbacks. Membrane switches can have a much shorter life expectancy compared to mechanical switches, especially under heavy use. They can likewise be much less tactile, which could affect individual responses during operation. If harmed, repairing them can be difficult and commonly calls for complete substitute. Inevitably, their level of sensitivity to extreme temperatures and environmental conditions might limit their effectiveness in particular settings. Stabilizing these benefits and drawbacks will certainly assist you determine if membrane layer buttons are the appropriate fit for your task.

Often Asked Concerns

How Much Time Do Membrane Layer Changes Usually Last?

Membrane changes generally last between 5 to ten years, depending on use and environmental conditions. You'll wish to evaluate factors like wear, direct exposure to moisture, and temperature changes to determine their long life successfully.

Can Membrane Switches Over Be Customized for Details Layouts?

Yes, you can customize membrane layer switches to fit certain styles (membrane switch manufacturer). You'll have the freedom to pick shades, shapes, and formats that match your job's demands, guaranteeing they blend perfectly with your total visual

What Is the Cost Range for Membrane Layer Change Production?

The expense range for membrane layer button manufacturing typically falls between $1 and $10 each, depending upon aspects like layout intricacy, quantity, and materials. You can obtain quotes from producers to find the very best choice.

Are Membrane Layer Switches Water-proof or Resistant?

Membrane buttons can be made to be waterproof or immune, relying on materials utilized and building approaches. If you require them for damp environments, ensure you specify those demands during the style procedure.

Exactly How Do Membrane Changes Compare to Conventional Switches?

Membrane buttons are usually thinner and extra flexible than standard switches, using a streamlined layout. They're usually much easier to clean and incorporate, however may not supply the responsive comments you're utilized to with mechanical alternatives.

Final thought

Report this page